Laser Cutting and Turret Punching Services

Laser Cutting Services.

With automatic loaders and unloaders, our Fiber and CO2 lasers ensure the fastest response times, providing you with exceptional efficiency. From mild steel to stainless steel and aluminum, we can cut through various materials with ease, meeting your exact specifications.

Here are the reasons why our customers are happy and satisfied with our laser cutting services:

- Faster turnaround times due to advanced machinery and automation.

- Reduced costs through improved efficiency and minimized secondary processes.

- High-quality parts with tight tolerances and clean edge cuts.

- Assurance of meeting customer specifications and delivery deadlines.

Amada ENSIS 9000 Watt AJ Fiber w/Tower

This 9ooo Fiber Watt Laser equipped with an automatic unload and load tower makes quick work of your cut part requirements. Our most powerful laser can handle our largest sheet sizes and move between the thickest and thinnest of materials with ease.

Maximum Sheet Size: 160″ x 80″

Maximum Thickness:

| Mild Steel | 1.0″ |

| Stainless Steel | 1.0″ |

| Aluminum | 1.0″ |

Amada 6000 Watt Fiber w/Tower

This 6ooo Watt Fiber Laser equipped with an automatic unload and load tower makes quick work with thinner gauge materials and is strong enough to cut through 3/4″ mild steel.

Maximum Sheet Size: 120″ x 60″ Maximum Thickness:

| Mild Steel | 0.865″ |

| Stainless Steel | 0.709″ |

| Aluminum | 0.630″ |

| Copper | 0.315″ |

| Brass | 0.315″ |

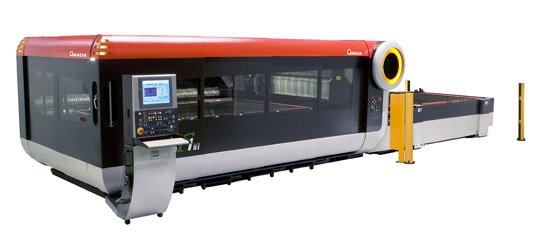

Amada 6000 Watt Fiber w/Tower

This 6ooo Fiber Watt Laser equipped with an automatic unload and load tower (not pictured) makes quick work of your cut part requirements.

Maximum Sheet Size: 120″ x 60″

Maximum Thickness:

| Mild Steel | 0.865″ |

| Stainless Steel | 0.709″ |

| Aluminum | 0.630″ |

| Copper | 0.315″ |

| Brass | 0.315″ |

Amada 4000 Watt Fiber w/Tower

This 4ooo Watt Fiber Laser equipped with an automatic unload and load tower cuts through tinner gauge materials two (2) to four (4) times faster than a comparable 4000 watt CO2 laser.

Maximum Sheet Size: 120″ x 60″

Maximum Thickness:

| Mild Steel | 0.865″ |

| Stainless Steel | 0.709″ |

| Aluminum | 0.630″ |

| Copper | 0.315″ |

| Brass | 0.315″ |

Amada 4000 Watt CO2

This 4000 Watt Laser is a workhorse in our stable capable of cutting some of the thickest steel in our operation.

Maximum Sheet Size: 120″ x 60″

Maximum Thickness:

| Mild Steel | 7/8″ |

| Stainless Steel | 1/2″ |

| Aluminum | 3/8″ |

Amada 4000 Watt CO2 Laser

Another workhorse in our stable, this laser is used to cut larger parts coming through the plant.

Maximum Sheet Size: 160″ x 80″

Maximum Thickness:

| Mild Steel | 7/8″ |

| Stainless Steel | 1/2″ |

| Aluminum | 3/8″ |

Automatic Storage Load and Unload Towers

Metalworking Solutions has three automatic storage unload and load towers feeding different lasers in the facility. These towers are configured to optimize green light time for the different lasers. Each tower has eight pallets capable of holding a little over 6000 lbs each. The automation from the towers allows for automatic unloading and loading of the lasers in less than five minutes per sheet of steel.

We can laser cut up to ¾ inch steel with our family of lasers. Three of our lasers are equipped with the auto load/unload towers. This enables us to configure our equipment with a variety of sheet sizes, thicknesses, and quantities for high volume unattended continuous cutting. In addition to the laser cutting of flat parts we have CNC Turrets as well. We easily cut and fabricate over two million parts per year from this facility.

All of our lasers are new machines with advanced features such as flying optics, linear drives and beam adjustments which result in tight tolerance parts with the cleanest edge cuts in the industry. We can improve your overall costs as a result of our machine speeds, lean operations, plus greatly reduce your typical secondary grinding and fit up costs on your assembly lines.

Our lasers can handle up to 6’ x 12’ sheets of material and our nesting software maximizes material utilization. Quality Assurance through our Fabrivision Laser Scanner verifies and documents that we have made parts to your drawings and tolerances before moving to subsequent operations.

Delivering high quality, on-time, high-value products and services are our commitment to each and every customer, all the time, every time.

Combined Services – Lasers and Punches.

- Advanced Technology: Our Amada laser cutting machines and CNC turret punch equipment are equipped with cutting-edge features such as automatic loaders and unloaders, ensuring fast and efficient production processes.

- Skilled Team: Following our culture, our team of engineers, designers, and technicians are highly trained professionals with years of experience in the industry. They work closely with our clients to understand their unique requirements and deliver customized solutions customized to their specific needs.

- Quality Assurance: At Metalworking Solutions, quality is our top priority. We adhere to strict quality control measures throughout the fabrication process to ensure that every product meets the highest standards of excellence.

- Fast Turnaround: With our advanced equipment and streamlined processes, our laser cutting and turret punching services offer quick turnaround times without compromising on quality. Whether you need a single prototype or a large production run, we can deliver results on time and within budget.

Metalworking Solutions:

Your Go-To Source for Laser Cutting and Turret Punching Services.

Metalworking Solutions is your trusted partner for all your laser cutting and turret punching needs. With our advanced technology, skilled team, and commitment to quality, we can help in your projects with maximum precision and efficiency. Get in touch with us today to learn more about our services and how we can assist you with your next project.